Factory

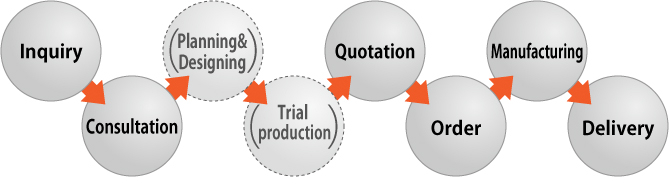

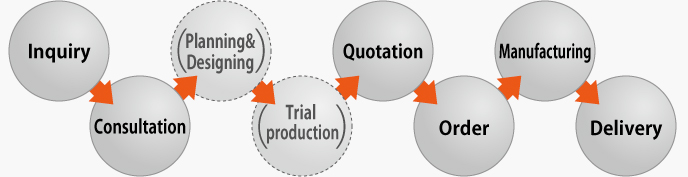

The Step

*"Planning&Designing" and "Trial production" will be incurred, if necessary

Wayo Shanghai Plant

Established as our own factory in China, the Shanghai Plant molds some of our regular items and our original products.

This plant also functions as a third-party inspection division for products manufactured by subcontractors.

Quality

A subsidiary company 100% owned by Wayo Co., Ltd. with more than 30 years experience in the sales promotion industry in Japan.

Japanese style quality control and the introduction of the education system by three Japanese staying in China (a person responsible for the factory is Mr. Kenji Wakura, one of the directors of Wayo Co. Ltd. in Japan)

Cost

Realized the most suitable and the lowest manufacturing cost by utilizing own manufacturing facilities and the network with local subcontractors within China.

Delivery

Convenient location in the suburb of Shanghai.

Strictly keeping delivery date to control the stock and production based on ERP system. The online delivery-order system with

customers is available.

Service

Convenient location in the suburb of Shanghai.

Strictly keeping delivery date to control the stock and production based on ERP system. The online delivery-order system with customers is available.

Wayo Shanghai Plant -

Equipment guide

Injection molding machines

All sorts of injection molding machines are owned by our factory.

Speedy sample production and flexible delivery are possible.

Overall in-store advertising molded-products can be manufactured in our own factory.

Inspection on products from third parties

Design and manufacturing know-how of

self-developed products by Wayo. Appropriate disposal environment of hazardous materials.

Processing of electronic products

Undertaking quality inspection on products produced by third parties in China. Experienced in tableware, sewn products, sanitary goods and gift products etc. for Japanese market.

Clean room

Facilities to handle food-related and electronic-related items with a highly controlled environment.

Secured traceability.

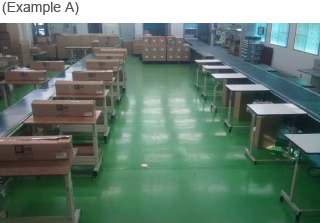

WAP(Koshigaya Factory)

WAP is our Last Process Department.

In order to meet every customers' requirement, we guarantee WAYO QUALITY with the production management; "Sideline work , Production line work , Assembly, and Delivery.

Access: 377 Hirakata, Koshigaya-City, Saitama. Japan 343-0002

number of satff:110

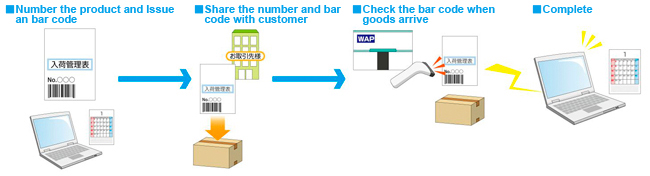

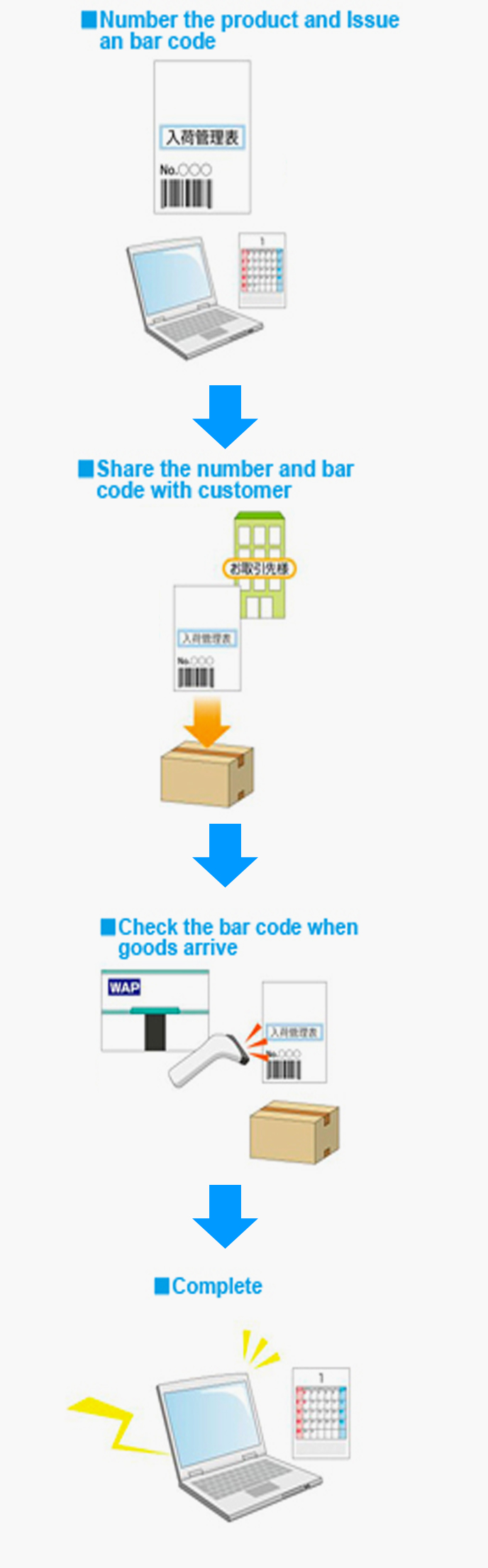

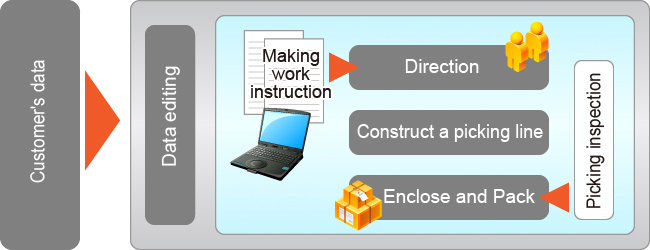

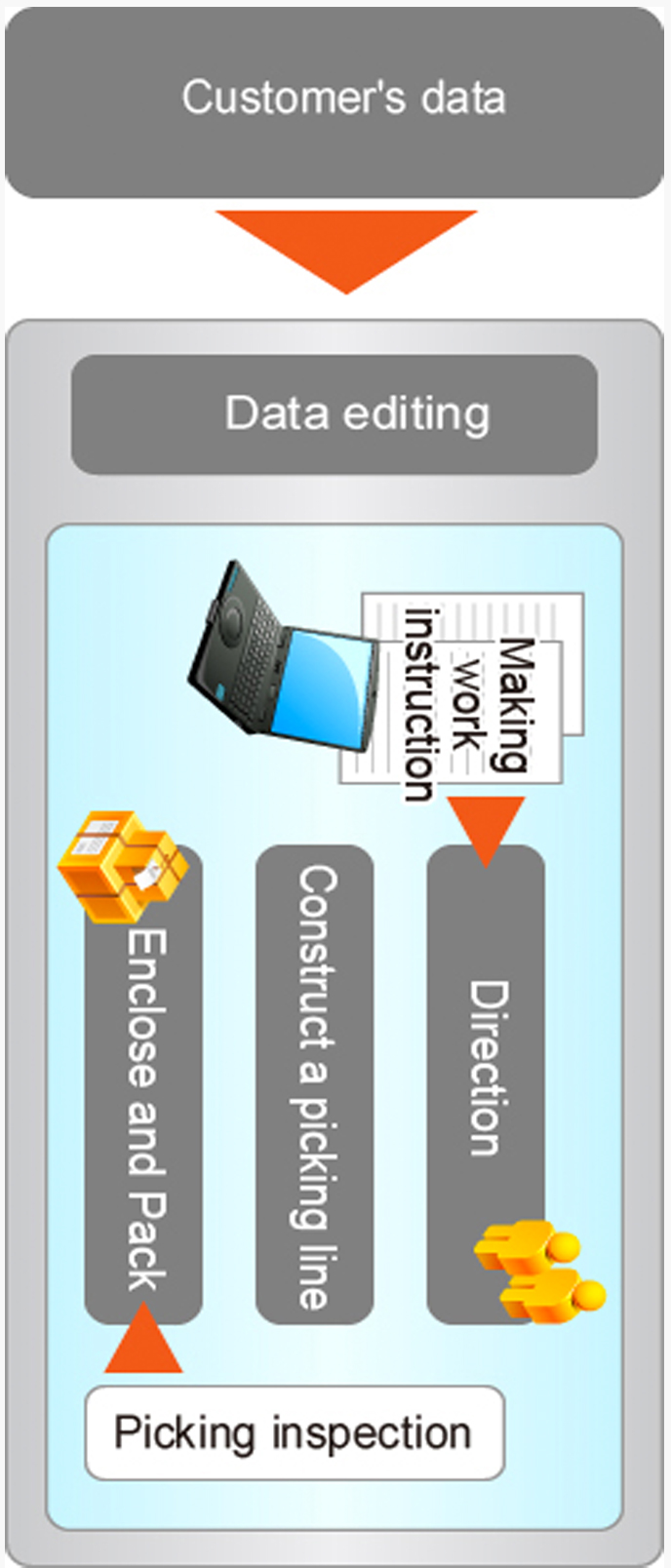

Production Management in WAP

Quality

Process Control by Original System

Customer-supplied products and stocks are in complete management with bar code.

Making every line stuff understand specification by using large monitor.

Quality Control Department

QC staff point out the critical processing point, before mass production.

Giving directions to sideline worker staff with operation manual

Cost

Quality control by quantifying intuition and sense based on experiences

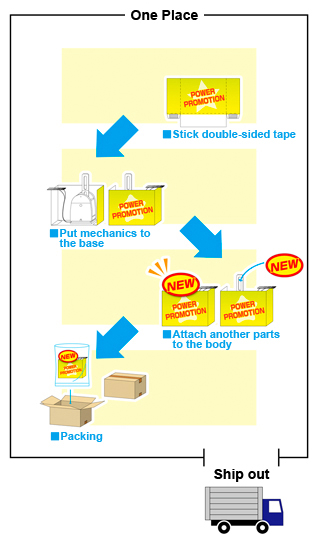

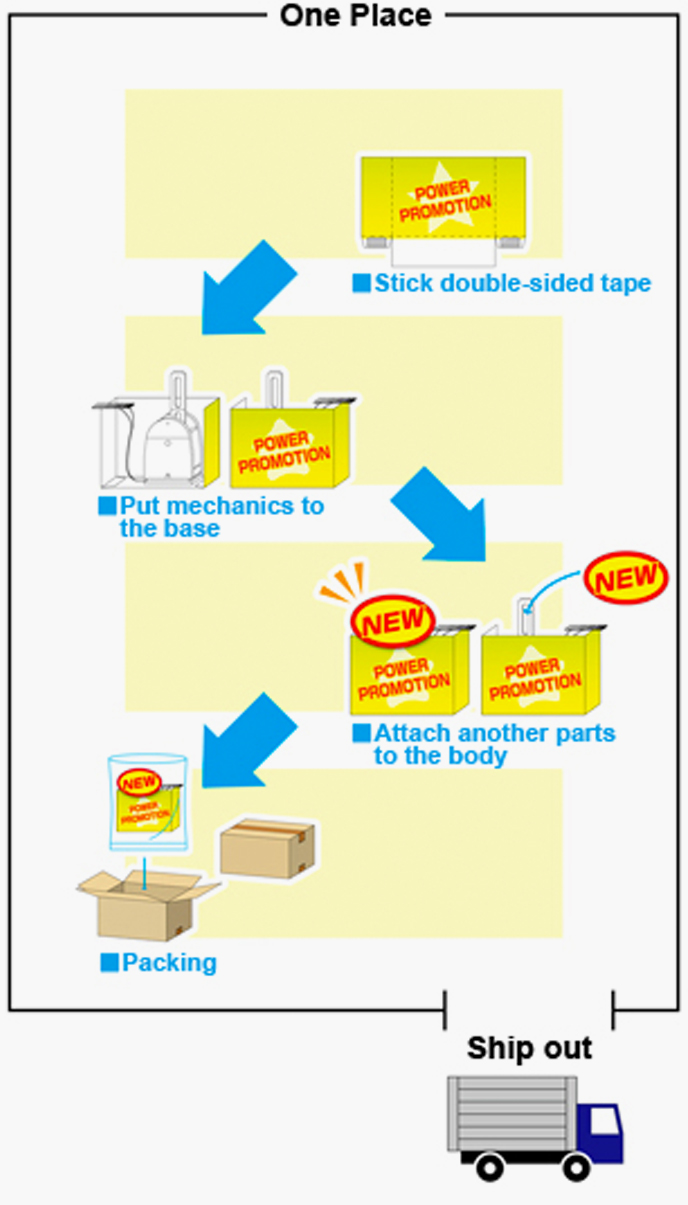

One products is made in one place

Cost and process-time reduction by not carrying the product to other place for another process.

Flexible Change of Production line(conveyer belt)

Convey layout can be changed easily as to production processes.

Delivery

Centralized management from picking to shipment

We can do picking work about plenty of and various kind of items, and reconcile them by data accurately.

All of the field staff share the item information and understand it in detail.

Service

- • Sideline work proccess

- • Assembly

- • Packing and Wrapping

- • Inspection

- • Storage

- • Inventory control